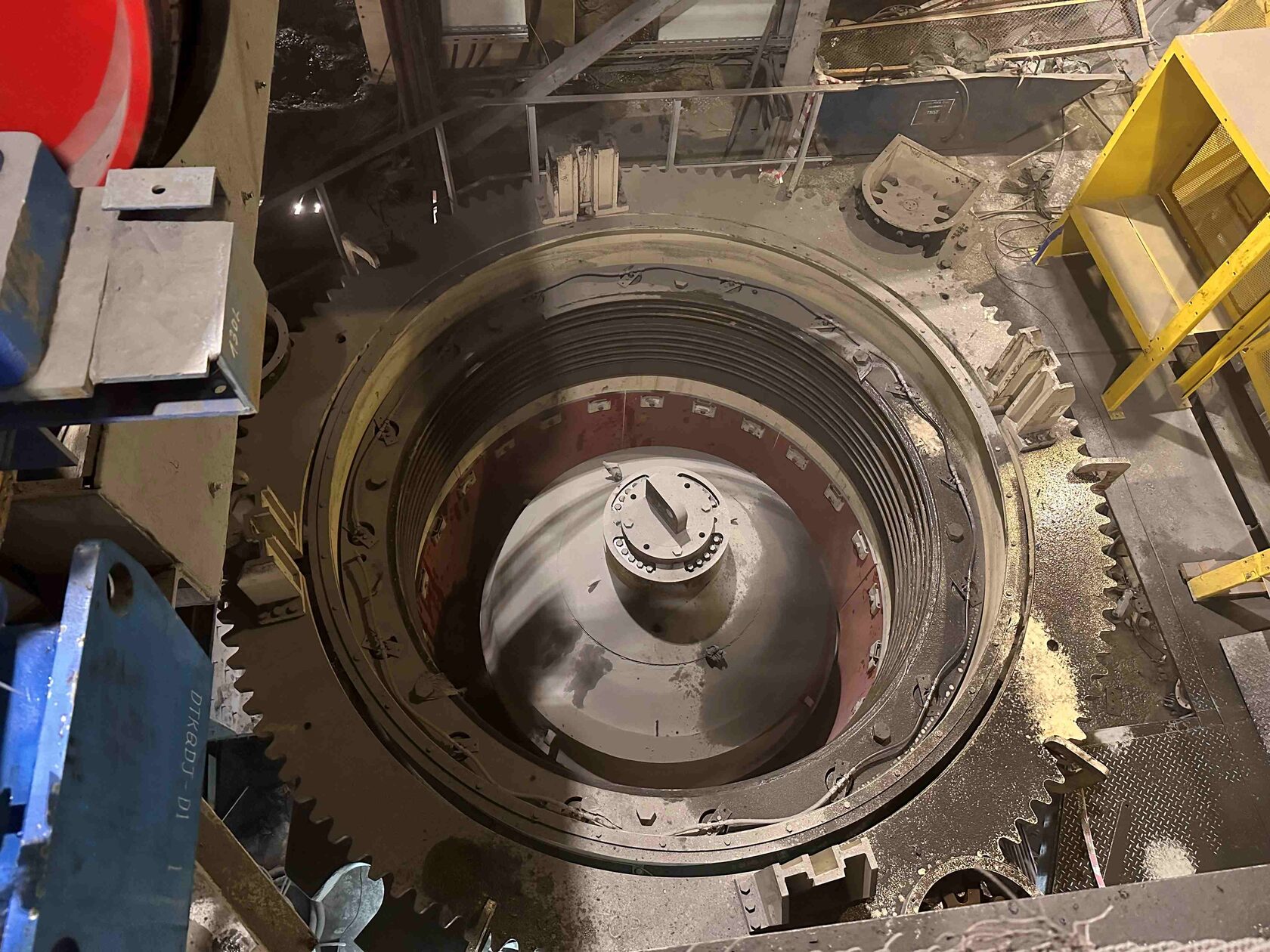

Iron ore mining and processing plant, Russia

Task:

Increase productivity and reduce downtime of crushing equipment and increase ore processing volumes to 47 million tons per year.

Technical solution:

• Dismantling of the entire line from the feed bin to the screen under the crusher

• Work on reworking the concrete foundation

• Work on reworking the metal structures of the marks

• Installation of a more productive crusher on a new concrete base

• Installation of marks and a service platform

• Installation of associated equipment and a feed belt conveyor with a gate and a shutter on the feed chute

Uniqueness of the project:

The project was implemented within the framework of the existing production in conditions of intense work with a combination of floors of work from the -6 m mark to the +13 m mark using a limited amount of shop lifting equipment.

Implementation of the project in a short time frame - 20 days, simultaneously with the scheduled and emergency work of the Customer.

Result:

Timely launch of fine crushing lines No. 5 and No. 8, achieving variability in the operation of fine crushing lines when planning repair and restoration work.

Task:

Increase productivity and reduce downtime of crushing equipment and increase ore processing volumes to 47 million tons per year.

Technical solution:

• Dismantling of the entire line from the feed bin to the screen under the crusher

• Work on reworking the concrete foundation

• Work on reworking the metal structures of the marks

• Installation of a more productive crusher on a new concrete base

• Installation of marks and a service platform

• Installation of associated equipment and a feed belt conveyor with a gate and a shutter on the feed chute

Uniqueness of the project:

The project was implemented within the framework of the existing production in conditions of intense work with a combination of floors of work from the -6 m mark to the +13 m mark using a limited amount of shop lifting equipment.

Implementation of the project in a short time frame - 20 days, simultaneously with the scheduled and emergency work of the Customer.

Result:

Timely launch of fine crushing lines No. 5 and No. 8, achieving variability in the operation of fine crushing lines when planning repair and restoration work.